Evaluating the warehouse layout may not be a priority for many businesses seeking a warehousing partner. However, it can significantly impact your operation and growth.

For most business types, the U-shaped warehouse layout is the best design as it minimises bottlenecks and unnecessary movement. Still, an I-shaped or L-shaped warehouse design works for others, depending on their product, storage needs, and other factors.

In this article, we will define warehouse layout and its designs. We will also highlight key considerations for determining which warehouse layout is best for your business.

What Is a Warehouse Layout?

A warehouse layout is the strategic arrangement of the facility’s four essential components: areas for receiving, storage, picking, and shipping.

- The receiving area is where your goods arrive and get inspected. Proper warehouse material handling is crucial in this section.

- The storage area is where staff arrange and keep goods received. Pallet racks, shelving, and other organising systems are here to ensure product safety and easy access.

- The picking area is the dedicated section for collecting ordered items. This area should have a streamlined system for accurate and fast order fulfilment.

- The shipping area is where staff pack collected items for dispatch.

A well-designed warehouse layout ensures that goods move efficiently from receiving to shipping. It also helps workers perform their tasks safely with minimal time and energy waste.

3 Types of Warehouse Layout Design

There are three main warehouse layout designs, and each type has its pros and cons. Let’s differentiate and see how they suit specific businesses.

1. U-Shaped Warehouse Layout

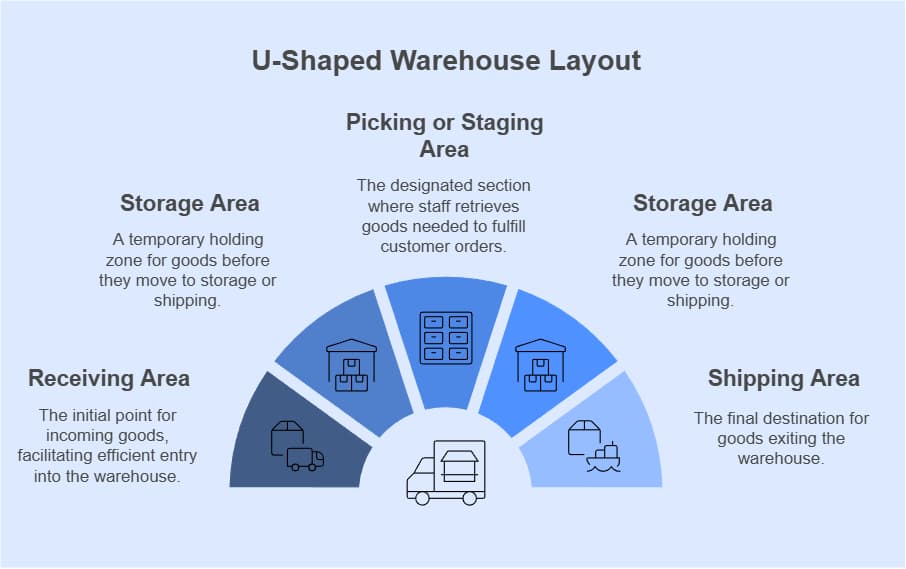

A U-shaped warehouse is the most common design as it is simple and easy to replicate. If you look at the image below, you can see that the receiving and shipping areas are right next to each other.

This arrangement allows the efficient sharing of dock resources like workers and product-handling equipment. It also facilitates quick transfer of goods that do not require long storage. We call this cross-docking.

| PROS | CONS |

| • Optimises space utilisation of small warehouses | • Receiving and shipping areas can become congested during peak times |

| • Minimises travel time for workers to access different warehouse areas | • Corners may not be fully utilised for storage due to U-shaped design |

| • Centralises operations for easier monitoring | • Complex layout may limit warehouse expansion potential |

| • Allows smooth flow of goods from inbound to outbound | • Requires careful planning to prevent bottleneck |

The U-shaped warehouse layout design is best for businesses with a wide range of fast-moving goods or high order volumes like:

- Online retailers with diverse product types or categories

- Grocery distributors with a variety of food items with varying shelf lives

- Electronic retailers with multiple product storage requirements

- Pharmaceutical wholesalers with several medications requiring specific storage settings

2. I-Shaped Warehouse Layout

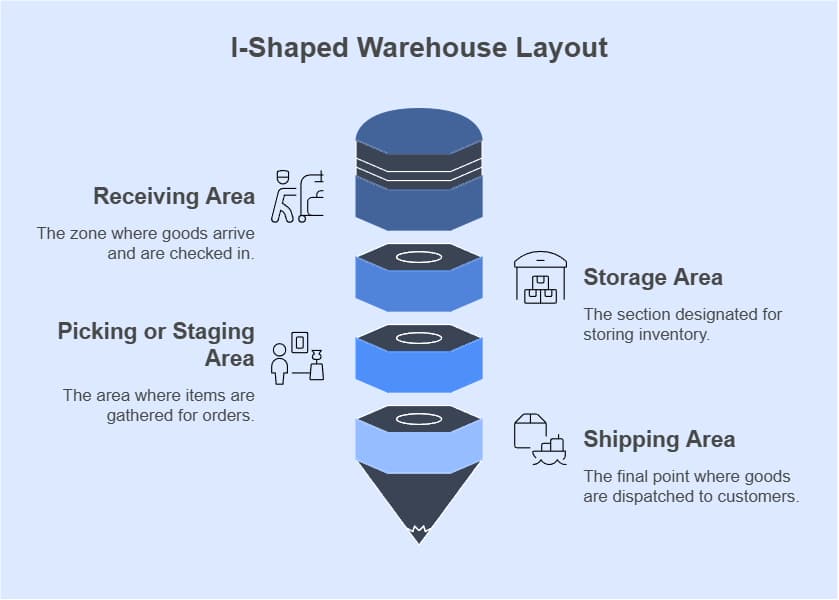

An I-shaped warehouse features a long central aisle within it. It is a suitable layout for conveyor belt systems where goods smoothly flow in a straight line.

| PROS | CONS |

| • Allows efficient use of small warehouse spaces | • Goods for loading or unloading may have to travel the entire length of the warehouse |

| • Creates a linear flow of items, preventing back-and-forth movement | • Access to goods from one warehouse section to the next can be time-consuming |

| • Provides a clear view of warehouse activities for easy monitoring | • Linear design makes it hard to store a wide variety of items |

| • Heavy equipment like forklifts can easily move up and down the straight aisle | • May not suit large warehouse spaces due to long travel time |

The I-shaped warehouse layout design is best for businesses with a limited range of bulky goods or high order volumes like:

- Distributors of lumber, pipes, rolled goods, and other large building materials

- Large e-commerce retailers with a high volume of similar products

- Wholesale food distributors handling large quantities of bulky items

- Paper manufacturers that require the transfer and storage of goods in a linear flow

3. L-Shaped Warehouse Layout

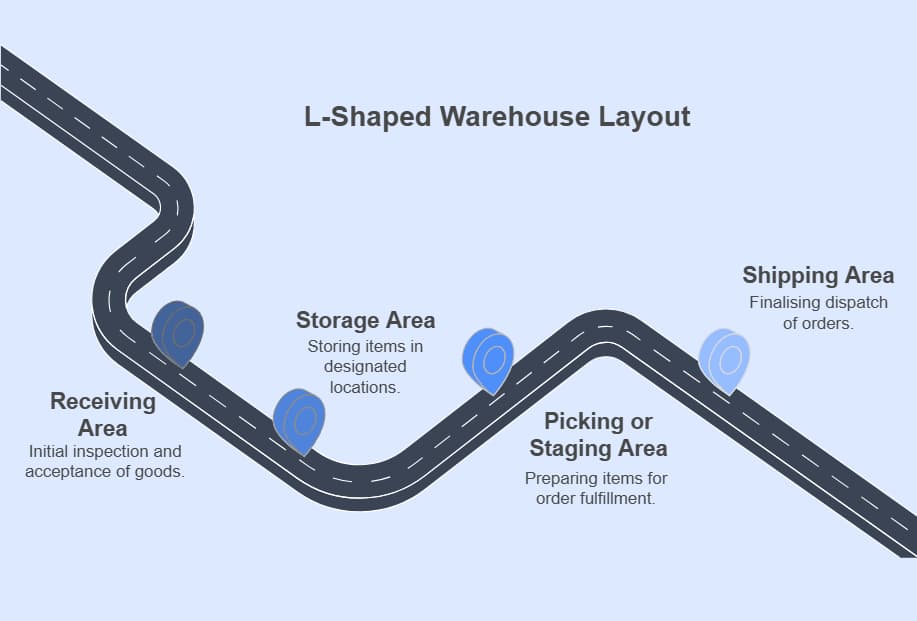

Irregularly shaped buildings or facilities often have an L-shaped warehouse design to maximise space.

As you can see in the image below, the receiving and shipping areas in this design are far apart. This setup allows operators to separate certain warehouse tasks and minimise traffic congestion.

Also, with the storage area in between the layout, staff can easily expand its storage capacity to the back of the warehouse.

| PROS | CONS |

| • Irregular shape allows more efficient use of corner spaces | • 90-degree angle makes forklift navigation and personnel movement challenging |

| • Ensures shorter travel distances between areas | • Often requires a large warehouse space to work efficiently |

| • Segregated sections keep warehouse functions organised | • Sharp angle of the layout can create bottlenecks if not properly planned |

| • Facilitates better traffic flow and security as receiving and shipping areas are on separate sides | • Usually requires special or additional equipment to connect the two separate sections |

The L-shaped warehouse layout design is best for businesses handling products of varying types, sizes, and storage conditions, such as:

- Manufacturers that need storage for raw materials and sellable inventory

- E-commerce businesses that store mixed product types, sizes, and handling requirements

- Businesses that need separate inbound and outbound docks for their temperature-sensitive or hazardous items

How to Choose the Best Warehouse Layout

The best warehouse layout design for your business mainly depends on the products you handle, the order volume, and other unique requirements. So, when choosing a warehousing partner, make sure to do the following first:

- Assess your inventory: analyse your products’ size, weight, and storage needs.

- Evaluate your daily operational needs and plans: review your order-picking processes, inventory turnover rates, and expected future growth.

- Observe actual warehouse operations: check if the layout can accommodate business changes like seasonal variations or new product lines.

- Ensure compliance with safety regulations: verify how well the warehouse keeps staff, equipment, and products secure.

Effective warehouse layouts satisfy all your current needs and plans for growth or expansion. It should help preserve the quality of your products and ensure timely deliveries while minimising bottlenecks or complaints.

Pick a Warehouse Layout that Suits Your Operations

All warehouses can store your goods and help you get them to customers. But not all facilities are the same. They vary in capacity, technology, and even layout designs. Your operational efficiency is affected if these do not fit your business needs.

So, when assessing a potential warehousing partner, check every aspect, including how goods move in and out of their facility. Their warehouse layout design should match your inventory characteristics, order volume, and storage requirements. That way, your warehousing provider can support your current processes and future growth.

At Effective Logistics, we have versatile warehouse solutions for optimal business productivity. Contact us to learn how our team can help improve your operations.